INVENTED IN CALIFORNIA, USA | CALL 312.622.6220 Daily 10AM-5PM PST

Acerca de

What is Needed To Manufacture this test?

First, understand the high life cycle of this product from creation to use to disposal:

1.Manufacture --> 2. Distribution --> 3. Receive Test --> 4. Taking Test --> 5.Process Test --> 6. Read Test Results --> 7. Contact Tracing & Data processing --> 8. Dispose of Test

Second, understand about the useful features of the test.

-

This is a single use disposable bio-degradable test to minimize medical waste.

-

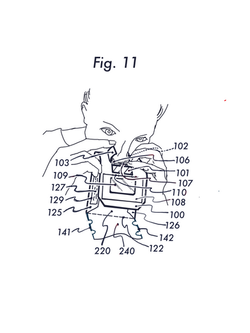

This test makes collecting the sample very easy for the user

-

Depending on various conditions, you can see visible results with the naked eye from 3 to 20 minutes with a very small sample size of several molecules.

-

The physical vehicle to carry the chemical testing elements can be used for a variety of pathogens (virus and bacteria). If you are testing for COVID-19, we recommend RPA.

-

The RT-RPA method is better than PCR as it processes in less time at a lower temperature (the range is 37–42 ◦C or 98.6–107.6 ◦F). RT-RPA takes 10–20 minutes to process. LAMP. RPA takes 60–90 min to process, This means RPA renders results faster.

-

-

The results are visible without the use of complex laboratory equipment. This means you can get tested in a parking lot and wait for results before you enter a building. It means that farm workers can test themselves and the farm animals while they are in a barn, or out at pasture.

-

The elements used are readily available (polypropylene nanofiber)

-

A single test can be sent by itself using standard mailing sorting machines, such as those used by the USPS ( United States Postal Service)

-

The used test can be sealed and sent to a processing center for further analysis and then it can be properly disposed of.

|  |  |

|---|---|---|

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |